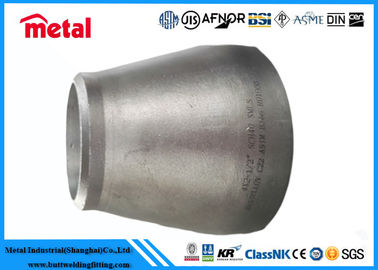

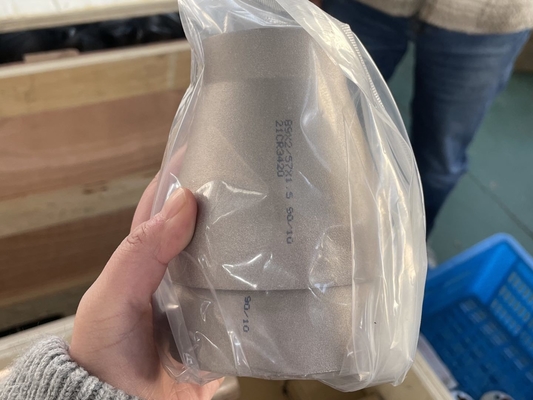

Butt-Welding Fitting Super Duplex Stainless Steel UNS S32750 Eccentric Reducer 1*3/4 ASME B16.9

Eccentric reducers refer to tubes of different diameters whose centers are not on

the same line, and tubes with one center on the same line are called concentric

reducers. The commonly used forming processes are shrink molding, expansion

molding or shrink and expand molding, and stamping can also be used for certain

specifications of different diameter pipes. Application of eccentric reducer The nozzle

diameter of the two ends of the eccentric reducer is different, so it is used to connect

different diameter pipe fittings or flanges to change the diameter. Tubes with different

diameters eccentric at both ends of the mouth, the center of the circle is on the same

axis, when the pipe diameter is calculated with the axis, the position of the pipe remains

unchanged, generally used for the change of gas or vertical liquid pipe diameter.

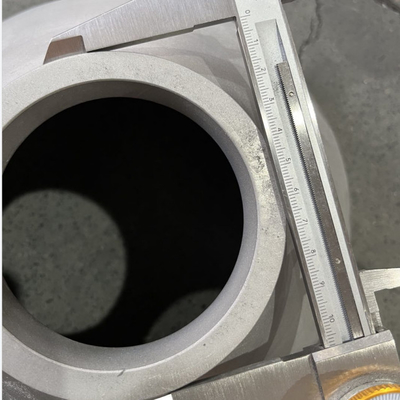

The roundness of the reducer should not be greater than 1% of the outer diameter of the

corresponding end, and the allowable deviation is ±3mm. The reducer material implements

SY/T5037, GB/T9711, GB/T8163, American Standard ASTM A106/A53 GRB, API 5L,

APT5CT, ASTM A105, ASTM A234, ASTM A106, DIN German Standard and customer

requirements standards

Reducer (large and small head) is a kind of pipe fittings used for pipe reducing. The forming

process commonly used is reduced diameter pressing, expansion pressing or diameter

reduction plus expansion pressing, and stamping can also be used for some specifications

of reducers.

a. Shrinking/expanding forming

The shrink forming process of reducer is to put the pipe blank equal to the diameter of the

large end of the reducer into the forming mold, and the metal moves along the mold cavity

and shrinks and forms by pressing it along the axial direction of the pipe blank. According

to the size of the diameter of the reducer, it is divided into one pressing forming or multiple

pressing forming. The figure below shows the schematic diagram of the reduced diameter

forming of concentric reducers.

Diameter expansion forming is the use of pipe blanks smaller than the diameter of the large

end of the reducer, and the inner diameter of the pipe blank is expanded along the inner

diameter of the pipe blank with an internal punching die. The diameter expansion process

mainly solves the situation that the reducer with a large diameter is not easy to be formed

by shrinking, and sometimes according to the forming needs of materials and products, the

method of diameter expansion and diameter reduction is combined.

In the process of shrinking or expanding the diameter deformation pressing, according to

different materials and diameter changes, it is determined to use cold pressing or hot pressing.

Under normal circumstances, cold pressing is used as much as possible, but hot pressing

should be used for severe work hardening caused by multiple reducer, thick wall thickness

or alloy steel materials.

b. Stamping forming

In addition to using steel pipes as raw materials to produce reducers, some specifications

of reducers can also be produced by stamping and forming steel plates. The shape of the

die used for stretching is designed according to the size of the inner surface of the reducer,

and the steel plate after blanking is stamped and stretched by the die.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!