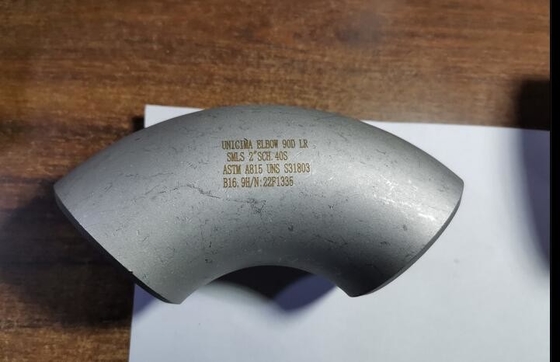

Seamless Butt Welding 90° Length Radius Elbow 12”SCH-STD ASTM N08825 Alloy 825

| Product Name |

Seamless Butt Welding 90° Length Radius Elbow 12 SCH-STD ASTM N08825 Alloy 825 |

| Certification |

/BV/ABS/LR/TUV/DNV/BIS/API/PED |

|

Material

|

ASTM

|

Carbon steel(ASTM A234WPB,,A234WPC,A420WPL6. |

| |

|

Stainless steel(ASTM A403 WP304,304L,316,316L,321. 1Cr18Ni9Ti, 00Cr19Ni10,

00Cr17Ni14Mo2, ect.)

|

| |

|

Alloy Steel:A234WP12,A234WP11,A234WP22,A234WP5,

A420WPL6,A420WPL3 |

| |

DIN

|

Carbon steel:St37.0,St35.8,St45.8 |

| |

|

Stainless steel:1.4301,1.4306,1.4401,1.4571 |

| |

|

Alloy steel:1.7335,1.7380,1.0488(1.0566) |

| |

JIS

|

Carbon steel:PG370,PT410 |

| |

|

Stainless steel:SUS304,SUS304L,SUS316,SUS316L,SUS321 |

| |

|

Alloy steel:PA22,PA23,PA24,PA25,PL380 |

| |

GB

|

10#,20#,20G,23g,20R,Q235,16Mn, 16MnR,1Cr5Mo,

12CrMo, 12CrMoG, 12Cr1Mo |

| Standard Specification |

ASTM,JIS,BS,DIN,UNI etc. |

| Qualification |

ISO9001, API,CE |

| Equipment |

Pushing Machine,Beveling Machine,Sand Blasting Machine |

| Pressure |

Sch5--Sch160,XXS |

| Standard |

ASME,ANSI B16.9; DIN2605,2615,2616,2617,JIS B2311 ,2312,2313; EN 10253-1 ,EN 10253-2 |

| Minimum Order Quantity |

1pcs |

| Supply Ability |

3,0000pcs per month |

| Price |

Depending on quantity |

| Supply Ability |

3,0000pcs per month |

| Packing |

PLY-wooden case or pallet or as for clients' requirements |

| Application |

Petroleum, chemical, machinery, electric power, shipbuilding, papermaking, |

|

Advantages

|

1. 32 + years of production experience at your service.

2. The fastest delivery

3. The lowest price

4. Most comprehensive standards and materials for your choice.

5. 100% export.

6. Our products EXPORT to Africa, Oceania, mid east, eastern Asia, Western Europe etc.

|

Introduction

Elbow is a commonly used connecting pipe fitting in plumbing installation. It is used for the connection at the bend of the pipeline and to change the direction of the pipeline.

Other names: 90 ° elbow, right angle bend, love bend, stamping elbow, pressing elbow, machine-made elbow, welding elbow, etc.

Purpose: connect two pipes with the same or different nominal diameter to make the pipeline turn 90 °, 45 °, 180 ° and various degrees.

Bending radius less than or equal to 1.5 times of pipe diameter belongs to elbow, and bending radius greater than 1.5 times of pipe diameter belongs to elbow

Overview and features

High nickel content makes the alloy have effective stress corrosion cracking resistance. It has good corrosion resistance in various media, such as sulfuric acid, phosphoric acid, nitric acid and organic acid, and alkali metals such as sodium hydroxide, potassium hydroxide and hydrochloric acid solution. The high comprehensive performance of Incoloy 825 is reflected in the Nuclear Combustion dissolver with various corrosive media, such as sulfuric acid, nitric acid and sodium hydroxide are treated in the same equipment.

NO8825 welding

The welding of Incoloy 825 must be carried out in annealed state, and the stains, dust and various marks must be cleaned with stainless steel wire brush. When welding at the root of the weld, in order to obtain the best quality of the root weld, the operation must be very careful (argon 99.99), so that the weld will not produce oxide after the root welding. The color produced by welding heat affected zone shall be brushed off with stainless steel brush when the weld area is not cooled.

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is the delivery ?

A: 15-30 working days

Q3: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

If you want to get more information of the products, send me e-mail or by skype, whatsapp etc.

.

If any questions,you can call me mobile phone at any times:0086-15710108231

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!