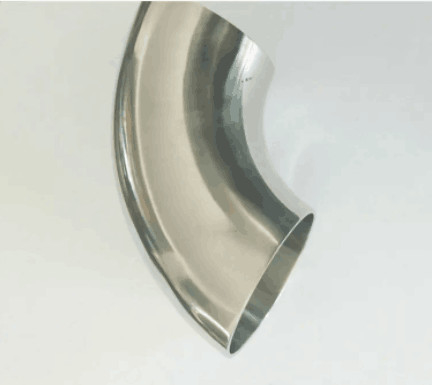

ELBW-4-45D-S40-A815 - ELBOW 4", 45 DEG, LR, SCH 80S, BE, ASME B 16.9 A 815 WPS UNS S31803

| Products |

ELBW-4-45D-S40-A815 - ELBOW 4", 45 DEG, LR, SCH 80S, BE, ASME B 16.9 A 815 WPS UNS S31803 |

| Item |

Elbow L/R S/R,Equal Tee,Reducing Tee,Concentric Reducer,Eccentric Reducer,Cap, Bend |

| Standard |

ASME |

ANSI B16.9,ANSI B16.28,MSS-SP-75 |

| |

DIN |

DIN2605,DIN2615, DIN2616, DIN2617, DIN28011 |

| |

SGP |

JISB2313 |

| |

EN |

EN10253-1 EN10253-2 |

| Material |

ASME |

A234 WPB,A234 WP1,A234 WP5,A234,WP9, |

| |

|

A234 WPB11,A234 WPB12,A234 WPB22,WP91, |

| |

|

A420,WPHY42,WPHY52,WPHY60,WPHY65, |

| |

|

WPHY70,WP304,WP304L,WP304H,WP316, |

| |

|

WP316L,WP321,WP347,WP347H |

| |

DIN |

ST37.0,ST35.8,ST45.8,S235JR,P235GH,P265GH, |

| |

|

10CrMo910,15CrMo,12Cr1MoV |

| |

JIS |

JIS G3454,STPG370,TPG410 |

| Surface |

Black paint/bright paint/Galvanized |

| Marking |

As customer’s requirements |

| Package |

By strong plywood cases |

| Delivery |

Within 30 days |

| Certificate |

PED, ISO9001:2008 |

v

Introduction to elbow

In the pipeline system, elbow is a pipe fitting that changes the direction of the pipeline. According to the angle, there are three most commonly used elbows: 45 ° and 90 ° 180 °, and other abnormal angle elbows such as 60 ° are also included according to the needs of the project. Elbow materials include cast iron, stainless steel, alloy steel, malleable cast iron, carbon steel, non-ferrous metals and plastics.

The connection methods with pipes include: direct welding (the most commonly used method) flange connection, hot-melt connection, electric fusion connection, threaded connection and socket connection. According to the production process, it can be divided into: welding elbow, stamping elbow, push elbow, casting elbow, butt welding elbow, etc. Other names: 90 degree elbow, right angle bend, etc.

Development trend of duplex stainless steel

It's worth noting LDX 2101 duplex stainless steel (21.5% Cr, 5% Mn, 1.5% Ni, 0.22% n) developed by Avesta polarit AB, Sweden, improves the nitrogen in the steel, obtains stable austenite, has good phase equilibrium and structural stability, and is resistant to the precipitation of intermetallic phase

It is not sensitive to precipitation. The impact value decreases to 50J only after holding for 10h at 650 ℃, which is the most sensitive temperature for precipitation. Its microstructure stability is better than that of 2205 steel. The steel has high strength, corrosion resistance equivalent to 304, can be welded, and its life cycle cost is lower than that of austenitic stainless steel

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is the delivery ?

A: 15-30 working days

Q3: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

If you want to get more information of the products, send me e-mail or by skype, whatsapp etc.

.

If any questions,you can call me mobile phone at any times:0086-15710108231

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!