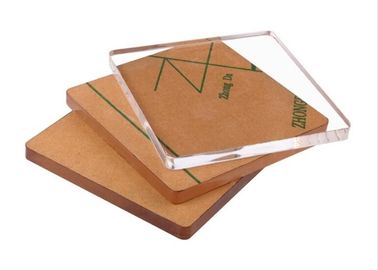

Unbreakable Acrylic Plate Cast Acrylic Sheets 2mm -200mm Clear Acrylic Board PMMA

Quick Details

Commodity name: PMMA board

Chinese name: acrylic or acrylic, plexiglass

English name:acrylic

Chemical name: Polymethyl methacrylate

|

Density

|

1.2g/cm3 |

| Color |

clear, transparent, marble,frosted,mirror ,red,blue,white,black ,

more than 200 kinds of colors. No fading colour in outdoor at least 8-10 years.

|

| Material |

adopt the pure LUCITE, high quality MMA raw material. |

| Technology |

cast acrylic sheet production process |

| Equipment |

Imported glass models (from Pilkington Glass in U. K. ) |

| Quality |

acrylic sheet conforms to the environmental protection standard, already through

SGS environmental protection authentication.

|

| payment |

L/C, T/T, Western Union, MoneyGram, Paypal and so on |

| MOQ |

50PCS |

| Delivery |

6-9days after confirm your order |

Amorphous thermoplastic polymer with high transparency, relative density (30 ℃/4℃) 1.188-1.22. High transparency, light transmittance 90%-92%, higher than inorganic glass, and can pass through ultraviolet light up to 73.5%. Refractive index 1.49. High mechanical strength, good toughness, tensile strength 60-75mpa, impact strength 12-13kj /m, higher than inorganic glass 8-10 times. It is stretchable and directional, and the impact strength is increased by 1.5 times. It has excellent resistance to ultraviolet and atmospheric aging. The vitrification temperature is 80-100 ℃, and the decomposition temperature is >200 ℃. The service temperature is -40 ~ 80℃. Resistance to alkali, dilute acid, water soluble inorganic salts, alkanes and fats. Soluble in dichloroethane, chloroform, acetone, glacial acetic acid, dioxane, tetrahydrofuran, ethyl acetate, insoluble ethanol, ether, petroleum ether, etc. Good electrical insulation. PMMA has the advantages of light weight, low price and easy to shape.

Product use

Its molding methods include casting, injection molding, mechanical processing, thermal molding and so on. In particular, injection molding, can be mass production, simple process, low cost. Therefore, its application is becoming more and more extensive. At present, it is widely used in instrument parts, automobile lamps, optical lenses, transparent pipes and so on.

Acrylic, also known as the plexiglass of special treatment, is a replacement product of plexiglass. The light box made of acrylic has the characteristics of good light transmittance, pure color, rich color, beautiful and smooth, giving consideration to both effects of day and night, long service life, and does not affect the use. In addition, acrylic sheet and aluminum plastic board profiles, advanced screen printing can be perfectly combined to meet the needs of businesses, acrylic plastic is to improve the level of stores, unified corporate image of the best outdoor advertising form. "Yakeli" is a transliterated word, which is ACRYLIC. It's a chemical material. Chemical name "PMMA" is a kind of polyacrylate, commonly known as "after special treatment of plexiglass", in the application industry, the raw materials of acrylic generally in the form of particles, plates, pipes. Acrylic acid is a generic name for both Acrylic acid and methacrylic acid chemicals. Including monomers, plates, grains, resins and composites, acrylic plates are made of methyl methacrylate (MMA) polymerized plexiglass, which is derived from the commercial name "Oroglas" (a PMMA plate) and comes from "Organic Glass" (also known as plexiglass).

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!