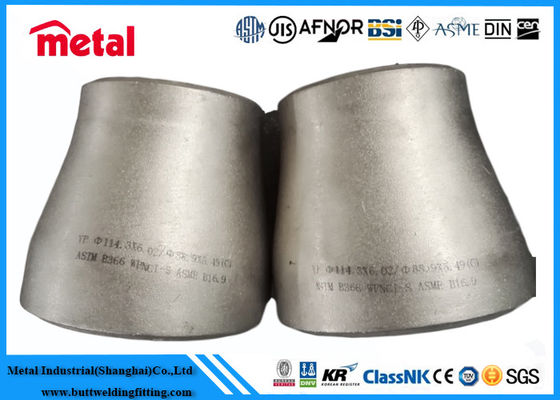

Inconel 601 Alloy Steel Pipe Fittings 2*11/2'' CONC. REDUCER ANSI B SCH10

Inconel 601 is a nickel-chromium-molybdenum alloy designed to resist a wide range of severely corrosive environments, pitting and crevice corrosion. This nickel steel alloy also displays exceptionally high yield, tensile, and creep-rupture properties at high temperatures. This nickel alloy is used from cryogenic temperatures up to long term service at 1200° F. One of the distinguishing features of Inconel 718’s composition is the addition of niobium to permit age hardening which allows annealing and welding without spontaneous hardening during heating and cooling. The addition of niobium acts with the molybdenum to stiffen the alloy’s matrix and provide high strength without a strengthening heat treatment. Other popular nickel-chromium alloys are age hardened through the addition of aluminum and titanium. This nickel steel alloy is readily fabricated and may be welded in either the annealed or precipitation (age) hardened condition. This is used in a variety of industries such as aerospace, chemical processing, marine engineering, pollution-control equipment, and nuclear reactors.

Inconel 601 is a nickel-chromium alloy used for applications that require resistance to corrosion and heat. This nickel alloy stands out due to its resistance to high temperature oxidation, remaining highly resistant to oxidation through 2200° F. Alloy 601 develops a tightly adherent oxide scale which resists spalling even under conditions of severe thermal cycling. This nickel alloy has good high temperature strength, and retains its ductility after long service exposure. It has good resistance to aqueous corrosion, high mechanical strength, and is readily formed, machined and welded. Inconel 601’s properties make it a material of broad utility in fields like thermal processing, chemical processing, pollution control, aerospace, and power generation. However, alloy 601 is not suggested for use in strongly reducing, sulfur bearing environments.

In what form is Inconel 601 available at TOBO?

· Sheet

· Plate

· Bar

· Pipe & Tube (welded & seamless)

· Fittings (i.e. flanges, slip-ons, blinds, weld-necks, lapjoints, long welding necks, socket welds, elbows, tees, stub-ends, returns, caps, crosses, reducers, and pipe nipples)

· Wire

What are the characteristics of Inconel 601?

· Outstanding oxidation resistance to 2200° F

· Resists spalling even under severe thermal cycling conditions

· Highly resistant to carburization

· Good creep rupture strength

· Metallurgical stability

Chemical Composition, %

| Ni |

Cr |

Al |

C |

Mn |

Si |

Fe |

| 61.5 |

22.5 |

1.4 |

.05 |

.3 |

.2 |

14 |

In what applications is Inconel 601 used?

· Chemical Processing

· Aerospace

· Heat treating industry

· Power generation

· Heat treating muffles and retorts

· Radiant tubes

· Catalyst support grids in nitric acid production

· Steam superheater tube supports

ASTM Specifications

| Pipe Smls |

Pipe Welded |

Tube Smls |

Tube Welded |

Sheet/Plate |

Bar |

Forging |

Fitting |

Wire |

| B167 |

B517 |

B167 |

- |

B168 |

B166 |

B564 |

B366 |

B166 |

Mechanical Properties

Typical room temperature Properties

| Tensile (psi) |

.2% Yield (psi) |

Elongation (%) |

| 80,000 |

30,000 |

35 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!