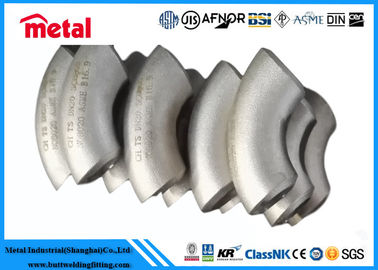

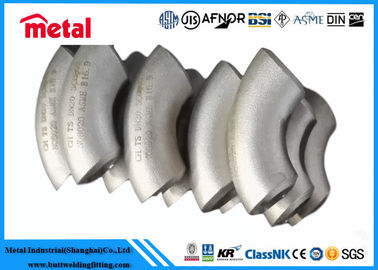

ASTM B366 WPNC 90 Degree Seamless Elbow Long Radius DN80 SCH80

Product name: Alloy 400/Monel 400/NO4400/NS111/2.4360/ASTM B366 WPNC;

General international names:MONEL alloy400,UNS N04400, NiCu30Fe W-Nr: 2.4360,Nicorros-alloy400,ATI400,,NAS NW400

National standards: ASTM B127/ASME SB-127, ASTM B163/ASME SB-163, ASTM B165/ASME SB-165

Main components: (C)≤0.30,(Ni) ≥ 63.0,(Si)≤0.5,(S)≤0.024,(Fe) ≤2.5,(Al) ≤2.0,(Cu) 28.0 ~34.0

- Physical Properties: Density: 8.9g/cm3, melting point: 1300-1350 ℃

| Product Name |

90° Seamless Elbow |

| Size |

1/2’’~10’’(Seamless);12’’~72’’(Welded) |

| Thickness |

Sch5S~Sch160XXS |

| Manufacture Standard: |

ASME B16.9,ASME B16.11,ASME B16.28 ,MSS SP-43,JISB2311,JIS B2312,JIS B2313,DIN 2605,DIN2606 ,DIN2615,DIN2616 ,BG12459-90,

GB/T13401,HGJ514 ,SH3408 ,SH3409, HG/T21635, HG/T21631,

|

| Duplex steel |

UNSS44627, UNS S42900, UNS S43000, UNS S43036, UNS S44600,

UNS S32101, UNS S32750, UNS S32950, UNS S32760, UNS S32974

UNS S32205, UNS S41008, UNS S41500, UNS N44626, UNS S31803

|

| Nickel alloy steel |

Alloy 400/Monel 400/NO4400/NS111/2.4360/ASTM B366 WPNC;

Alloy K-500/Monel K-500/NO5500/2.475;

Alloy 600/Inconel 600/NO6600/NS333/2.4816;

Alloy 601/Inconel 601/NO6001/2.4851;

Alloy 625/Inconel 625/NO6625/NS336/2.4856;

Alloy 718/Inconel 718/NO7718/GH169/GH4169/2.4668;

Alloy 800/Incoloy 800/NO8800/1.4876;

Alloy 800H/Incoloy 800H/NO8810/1.4958;

Alloy 800HT/Incoloy 800HT/NO8811/1.4959;

Alloy 825/Incoloy 825/NO8825/2.4858/NS142;

Alloy 925/Incoloy 925/NO9925;

Hastelloy C/Alloy C/NO6003/2.4869/NS333;

Alloy C-276/Hastelloy C-276/N10276/2.4819;

Alloy C-4/Hastelloy C-4/NO6455/NS335/2.4610;

Alloy C-22/Hastelloy C-22/NO6022/2.4602;

Alloy C-2000/Hastelloy C-2000/NO6200/2.4675;

Alloy B/Hastelloy B/NS321/N10001;

Alloy B-2/Hastelloy B-2/N10665/NS322/2.4617;

Alloy B-3/Hastelloy B-3/N10675/2.4600;

Alloy X/Hastelloy X/NO6002/2.4665;

Alloy G-30/Hastelloy G-30/NO6030/2.4603;

Alloy X-750/Inconel X-750/NO7750/GH145/2.4669;

Alloy 20/Carpenter 20Cb3/NO8020/NS312/2.4660;

Alloy 31/NO8031/1.4562;

Alloy 901/NO9901/1.4898;

Incoloy 25-6Mo/NO8926/1.4529/Incoloy 926/Alloy 926;

Inconel 783/UNS R30783; |

| Package |

Wooden cases, pallets, nylon bags or according to the customers' requirements |

| MOQ |

1pcs |

| Delivery time |

10-100 days depending on quantity |

| Payment terms |

T/T or Western Union or LC |

| Shipment |

FCA Tianjin/Shanghai, CFR, CIF, etc |

| Application |

Petroleum/Power/Chemical/Construction/Gas/Metallurgy/Shipbuilding etc |

| Remarks |

Other materials and drawings are available. |

Elbows:

We offer Bend and Elbow in stainless steel, carbon steel and alloy steel material. These fittings are also available in monel, nickle, inconel, hastalloy, copper, brass, titanium material to meet the requirements of clients. Our range is designed in line with international quality standard and is widely used in different applications across industries.

Form : Elbows in long & short radius in 45 deg, 90 deg, 180 deg

Size : 1/8" NB to 48" NB (Seamless & Welded)

Wall thickness : Sch.5S to Sch: XXS.

Chemical Properties

| Grade |

Ni |

Fe |

C |

Mn |

Si |

Cu |

Al |

S |

| Monel 400 |

63.0 min |

1.0-2.5 |

0.3 max |

2.0 max |

0.5 max |

28.0-34.0 |

0.50 max |

0.02 MAX |

Corrosion resistance and main operating environment:

In general, the corrosion resistance of Monel400 is better than that of nickel-copper. It is more resistant to corrosion of reducing medium than pure nickel, more resistant to corrosion of oxidizing medium than pure copper, and very good to corrosion resistance of sulfuric acid, phosphoric acid and carbon. In particular, the corrosion resistance of hydrochloric acid, hot alkali also has excellent corrosion resistance. Monel400 alloy has excellent corrosion resistance in fluorine, hydrochloric acid, sulfuric acid, hydrofluoric acid and there derivatives. It is also more resistant to corrosion in seawater than copper based alloys.

Monel400 is a nickel-copper nickel-based alloy that can be deformed and machined. It has good resistance to seawater corrosion and chemical corrosion, and strong resistance to chloride stress corrosion cracking. The alloy is one of the few that can be used in fluoride. It has good resistance to oxide stress fission corrosion in hydrofluoric acid and fluorocarbon media, such as seawater and brine environments.

Applications: sulfuric acid and hydrofluoric acid equipment, Marine heat exchangers, desalination equipment, salt production equipment, Marine and chemical processing equipment, propeller shaft and pumps, gasoline and water tanks, etc

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!