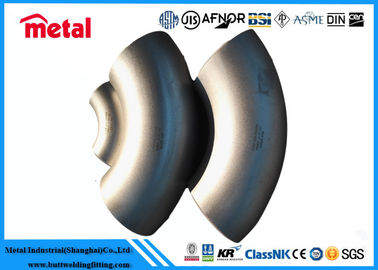

Inconel625, UNS N06625 90 Degree Elbow Long Radius Pipe Fittings

Product name: Inconel625/UNS N06625

General international names: Inconel Alloy 625,NS336,NAS 625,W.Nr.2.4856,UNS NO6625,Nicrofer S 6020-FM 625,ATI 625

National standards: ASTM B443/ASME SB-443,ASTM B444/ASME SB-444,ASTM B366/ASME SB-366,ASTM B446/ASME SB-446,ASTM B564/ASME SB-564

Main components: (C)≤0.01,(Mn)≤0.50,(Ni)≥58,(Si)≤0.50,(P)≤0.015,(S)≤0.015,(Cr)20.0~23.0,(Fe) ≤5.0,(Al) ≤0.4,(Ti) ≤0.4,(Nb) 3.15~4.15,(Co) ≤1.0, (Mo)8.0~10.0

- Physical Properties: Density: 8.44g/cm3, melting point: 1290-1350 ℃

| Product Name |

90° Seamless Elbow |

| Size |

1/2’’~10’’(Seamless);12’’~72’’(Welded) |

| Thickness |

Sch5S~Sch160XXS |

| Manufacture Standard: |

ASME B16.9,ASME B16.11,ASME B16.28 ,MSS SP-43,JISB2311,JIS B2312,JIS B2313,DIN 2605,DIN2606 ,DIN2615,DIN2616 ,BG12459-90,

GB/T13401,HGJ514 ,SH3408 ,SH3409, HG/T21635, HG/T21631,

|

| Duplex steel |

UNSS44627, UNS S42900, UNS S43000, UNS S43036, UNS S44600,

UNS S32101, UNS S32750, UNS S32950, UNS S32760, UNS S32974

UNS S32205, UNS S41008, UNS S41500, UNS N44626, UNS S31803

|

| Nickel alloy steel |

Alloy 400/Monel 400/NO4400/NS111/2.4360/ASTM B366 WPNC;

Alloy K-500/Monel K-500/NO5500/2.475;

Alloy 600/Inconel 600/NO6600/NS333/2.4816;

Alloy 601/Inconel 601/NO6001/2.4851;

Alloy 625/Inconel 625/NO6625/NS336/2.4856;

Alloy 718/Inconel 718/NO7718/GH169/GH4169/2.4668;

Alloy 800/Incoloy 800/NO8800/1.4876;

Alloy 800H/Incoloy 800H/NO8810/1.4958;

Alloy 800HT/Incoloy 800HT/NO8811/1.4959;

Alloy 825/Incoloy 825/NO8825/2.4858/NS142;

Alloy 925/Incoloy 925/NO9925;

Hastelloy C/Alloy C/NO6003/2.4869/NS333;

Alloy C-276/Hastelloy C-276/N10276/2.4819;

Alloy C-4/Hastelloy C-4/NO6455/NS335/2.4610;

Alloy C-22/Hastelloy C-22/NO6022/2.4602;

Alloy C-2000/Hastelloy C-2000/NO6200/2.4675;

Alloy B/Hastelloy B/NS321/N10001;

Alloy B-2/Hastelloy B-2/N10665/NS322/2.4617;

Alloy B-3/Hastelloy B-3/N10675/2.4600;

Alloy X/Hastelloy X/NO6002/2.4665;

Alloy G-30/Hastelloy G-30/NO6030/2.4603;

Alloy X-750/Inconel X-750/NO7750/GH145/2.4669;

Alloy 20/Carpenter 20Cb3/NO8020/NS312/2.4660;

Alloy 31/NO8031/1.4562;

Alloy 901/NO9901/1.4898;

Incoloy 25-6Mo/NO8926/1.4529/Incoloy 926/Alloy 926;

Inconel 783/UNS R30783; |

| Package |

Wooden cases, pallets, nylon bags or according to the customers' requirements |

| MOQ |

1pcs |

| Delivery time |

10-100 days depending on quantity |

| Payment terms |

T/T or Western Union or LC |

| Shipment |

FCA Tianjin/Shanghai, CFR, CIF, etc |

| Application |

Petroleum/Power/Chemical/Construction/Gas/Metallurgy/Shipbuilding etc |

| Remarks |

Other materials and drawings are available. |

Corrosion resistance and main operating environment:

INCONEL 625 is a nickel as the main component of austenitic heat resistant alloy of nickel and chromium alloy containing molybdenum niobium solid solution strengthening effect of the low temperature to 1093, the anti-fatigue properties of ultra high strength and special, is widely used in aviation industry while the alloy is designed to adapt to the environment of high temperature strength, but the chromium molybdenum alloy of high content of corrosive medium, many from highly oxidizing environment to general corrosion environment, all have high fission corrosion resistance, erosion resistance spot show the feature of excellent corrosion resistance to chloride medium such as water geothermal water pollutionNeutral salt and salt water,INCONEL 625 also has superior corrosion resistance

Applications: Components of organic chemical processes containing chlorides, especially where acid chloride catalysts are used; Digesters and bleaching ponds for the pulp and paper industry; Absorption tower, reheater, flue gas inlet baffle, fan (moisture), stirrer, deflector and flue in flue gas desulfurization system; Manufacturing equipment and components for use in acidic gas environments; Acetic acid and acetic anhydride reaction generator; Sulfuric acid condenser; Pharmaceutical equipment; Bellows expansion joints and other industries and products.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!