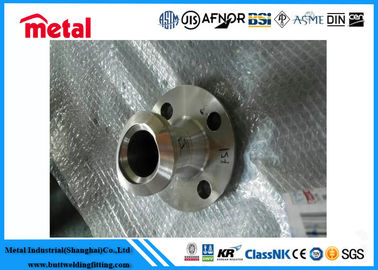

Forged Nickel Alloy Steel Flanges Nipo Flange Alloy S, UNS N06635

GENERAL CHARACTERISTICS OF ALLOY S

Alloy S is a nickel-base high-temperature alloy that has excellent oxidation resistance to 2000ºF (1095ºC),

along with good high-temperature and thermal fatigue strength

Product Description

| Product Name |

Nipo Flange |

| Standard |

ASME/ANSI B16.5/16.36/16.47A/16.47B/B16.48, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Type |

Special Flange: According to the drawing Picture |

| Materials |

Copper Nickel Alloy: ASTM B466 UNS C70600, ASTM B466 UNS C71500, CUNI90/10, CUNI70/30

Nickel Alloy: ASTM/ASME S/B366 UNS N08020, N04400, N06600, N06625, N08800, N08810, N08825, N10276,N10665,N10675

Super Stainless Steel: ASTM/ASME S/A182 F44, F904L, F317L, UNS S32750, UNS S32760

Stainless steel: ASTM/ASME S/A182 F304, F304L, F304H, F316, F316L, F321, F321H, F347H

Duplex Steel: ASTM A182 F51, F53, F55, UNS S31803, UNS S31254

Alloy Steel: ASTM/ASME S/ A182 F11, F12, F22, F5, F9, F91

Carbon Steel: ASTM/ASME S/A105, ASTM/ASME S/A350 LF2, ASTM/ASME S/A694/A694M, F42, F52, F56, F60, F65, F70....

ASTM A516 GRADE 70

|

| Dimension |

(150#,300#,600#): DN15-DN1500

900# : DN15-DN1000

1500#: DN15-DN600

2500#:D N15-DN300 |

| Test |

Chemical Component Analysis, Mechanical Properties, Metallurgical Analysis, Impact Testing, Hardness testing , Ferrite Testing, Inter granular corrosion testing, X-ray Inspection (RT), PMI, PT, UT, HIC & SSC test, etc. or as your requirement |

| Certificates |

API, ISO, SGS, BV, CE, PED, KOC, CCRC, PDO, CH2M HILL and etc. |

| Advantages |

1. Abundant stock and prompt delivery

2. Reasonable for whole packages and processes.

3. 15 years' QC team service & sales management API& ASTM trained engineers.

4. More than 150 customers spread worldwide. (Petrofac, G.S Engineer, Fluor, Hyundai Heavy industry, Kuwait National Oil, Petrobras, PDVSA, Petrol Ecuador, SHELL, etc.)

|

ASME/ANSI B16.5 stainless steel RF nipo-flange

Nipoflange is used in the pipe industry like a weldolet or a nipolet for a 90° branch connection.

A Nipoflange is a combination of weldolet, nipolet and flange.

Two different pipe branch connectionsOn the run pipe side a nipoflange is designed like a weldolet.

That means the branch connection on the run pipe side is a welding connection. On the other side there

it has a flange connection. The flange connection can be designed according to customers requirements

(acc. To DIN or ANSI).

| CHEMICAL ANALYSIS |

| C |

Carbon 0.02 max |

| Mn |

Manganese 0.30/1.00 |

| Si |

Silicon 0.20/0.75 |

| Cr |

Chromium 14.50/17.00 |

| Mo |

Molybdenum 14.00/16.50 |

| Al |

Aluminium 0.10/0.50 |

| Co |

Cobalt 2.00 max |

| Cu |

Coper 0.050 max |

| Fe |

Iron 3.00 max |

| B |

Boron .015 max |

| Ni |

Nickel 67 (bal) |

APPLICATIONS

This alloy was developed for conditions involving severely cyclical heating conditions where components

must be capable of retaining there strength and ductility after long exposure. The alloy is used extensively

in seal rings in gas turbine engines where it's low coefficient of thermal expansion is also important.

| Alloy |

Ni |

C |

Mn |

Fe |

S |

Si |

Cu |

Cr |

Al |

Ti |

Nb |

Mo |

| Nickel 200 |

99.5 |

0.08 |

0.2 |

0.2 |

0.005 |

0.2 |

0.1 |

-- |

-- |

-- |

-- |

-- |

| Nickel 200 |

99.5 |

0.01 |

0.2 |

0.2 |

0.005 |

0.2 |

0.1 |

-- |

-- |

-- |

-- |

-- |

| Monel 400 |

66.5 |

0.2 |

1 |

1.2 |

0.01 |

0.2 |

31.5 |

-- |

-- |

-- |

-- |

-- |

| Monel 401 |

42.5 |

0.05 |

1.6 |

0.4 |

0.008 |

0.1 |

|

-- |

-- |

-- |

-- |

-- |

| Monel K500 |

66.5 |

0.1 |

0.8 |

1 |

0.005 |

0.2 |

29.5 |

-- |

2.7 |

0.5 |

-- |

-- |

| Inconel 600 |

76 |

0.08 |

0.5 |

8 |

0.006 |

0.2 |

0.2 |

15.5 |

-- |

-- |

-- |

-- |

| Inconel 601 |

60.5 |

0.05 |

0.5 |

14.1 |

0.007 |

0.2 |

0.5 |

23 |

1.4 |

-- |

-- |

-- |

| Inconel 718 |

52.5 |

0.04 |

0.2 |

18.5 |

0.008 |

0.2 |

0.2 |

19 |

0.5 |

0.9 |

5.1 |

3 |

| Inconel X-715 |

73 |

0.04 |

0.5 |

7 |

0.005 |

0.2 |

0.2 |

15.5 |

0.7 |

2.5 |

1 |

-- |

| Incoloy 800 |

32.5 |

0.05 |

0.8 |

46 |

0.008 |

0.5 |

0.4 |

21 |

0.4 |

0.4 |

-- |

-- |

| Incoloy 803 |

32.0-

37.0 |

0.06-

0.10 |

≤1.5 |

|

≤0.015 |

≤1.0 |

≤0.75 |

25.0-

29.0 |

0.15-

0.60 |

0.15-

0.6 |

-- |

-- |

| Incoloy 825 |

42 |

0.03 |

0.5 |

30.4 |

0.02 |

0.2 |

2.2 |

21.5 |

0.1 |

0.9 |

-- |

3 |

Other Products

Nickel Alloys WNRF Flanges : Monel 400 & 500, Inconel 600 & 625, Incolloy 800, 825, Hastelloy C22,C276

Copper Alloys WNRF Flanges: Copper, Brass & Gunmetal

Incoloy Alloy Steel Flange : ASTM AB564 ,NO8800/ Alloy800, NO8810/ Alloy 800H, NO8811/Alloy 800HT

Hastelloy Steel Flange: ASTM AB564 , C276/ NO10276 , Monel Alloy 400 /NO4400, K500/NO5500,

FORGING

Forging of Alloy S alloy should be carried out at 2100/1600ºF (1145/870ºC) up to the final 20% of cross-section

reduction, this final 20% being carried out from about 1900ºF (1040ºC) to 1500ºF (815ºC).

HEAT TREATMENT

The alloy is solution treated at 1950ºF (1065ºC) and subsequently aged at temperatures from 800 through to

1600ºF (425 through 870ºC), where a whole range of tensile and impact properties may be obtained.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!