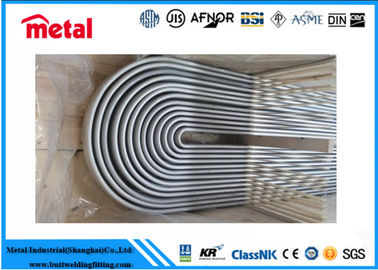

ASTM/ASME A/SA213 T11 U Tube Steel U-bent Tubes Seamless Ferritic

U Bend Tube are manufactured in our plant as per the customer requirements. Solution annealing after bend will

be process to lower the risidual stress, and followed by hydrostatic testing and dye penetrant testing if required.

| Priducts |

Dimensions |

Standards |

Materials |

Remarks |

| O.D |

W.T |

Length |

| U-bent Tubes for Heat Exchanger |

12.7-76.2mm

(1/2"-3") |

0.5-5.16mm

(0.02"-0.203") |

Leg Length: 15.24m(50')

Total Length: 32.00m(105)' |

ASTM/ASME A/SA213 |

T5, T11,T12, T22, T9, TP304/304L, TP304H, TP316/316L, TP347/347H, TP316Ti, TP321/321H, TP310S |

Seamless Ferritic and Austenitic Stainless Steel U-bent Tubes |

| ASTM/ASME A/SA249 |

TP304, TP304L, TP316, TP316L…… |

Welded Stainless Steel U-bent Tubes |

| ASTM/ASME A/SA789 |

UNS S31803/32205, UNS S32750…… |

Duplex Stainless Steel U-bent Tubes |

| ASTM/ASME A/SA163 |

Monel400, UNS N06600, 625, Incoloy800/800H, 825…… |

Seamless Nickel Alloy U-bent Tubes |

| ASTM/ASME A/SA268 |

TP405, TP409, TP410, TP430, TP439…… |

Ferritic and Martensitic Stainless Steel Seamless U-bent Tubes |

| Seamless and (Welded) Re-drawn Stainless Steel Feed Water Heater U-bent Tubes |

12.7-25.4mm

(1/2"-1") |

0.7-3.05mm

(0.028"-0.12") |

Leg Length: 15.24m(50')

Total Length: 32.00m(105)' |

ASTM/ASME A/SA668/213 ASTM/ASME A/SA803 |

TP304, TP304L, TP304LN TP316, TP316L, TP439 |

Low Pressure Feed Water Heater of Thermal Power Station |

Stainless Steel ubend :

ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L, 316TI, 316H, 304L

Carbon Steel ubend

ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel

ASTM A420 WPL3 / A420WPL6

Alloy Steel ubend

ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Duplex Steel ubend

ASTM A 815 UNS NO S 31803, S 32205, S 32760, S 32750

Copper Nickel

C70600(90:10), C71500(70:30), C71640.

Packing and Shipping

Package:Standard export carton packing.

Delivery time:stock 7-10 workign days after confirming order,detail delivery date should be decided according to

production season and order quantity.

TEST CERTIFICATE

Mill Test Certificate as per EN 10204 / 3.1

Advanced capabilities for U-bent tubes:

- Reliable bending machines

- Precision bending dies

- Eddy current test before bending

- Bending up to 105’(32m) developed length

- Electric resistance stress relief annealing after bending

- Hydrostatic test after bending

- OD and WT reduction Testing

- Full bending radius and tube legs tolerance check

- Stack-rack boxing

Nickel Alloy

Standard

· ASTM / ASME SB 336

· UNS 10276 (HASTELLOY C 276 )

· UNS 2200 (NICKEL 200 )

· UNS 2201 (NICKEL 201 )

· UNS 4400 (MONEL 400 )

· UNS 8020 (ALLOY 20 / 20) CB 3

· UNS 8825 INCONEL (825 )

· UNS 6600 (INCONEL 600 )

· UNS 6601 (INCONEL 601 )

· UNS 6625 (INCONEL 625 )

· UNS 5500(MONEL K500)

· UNS 8800(INCONEL 800)

· UNS 8810(INCONEL 800H)

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!