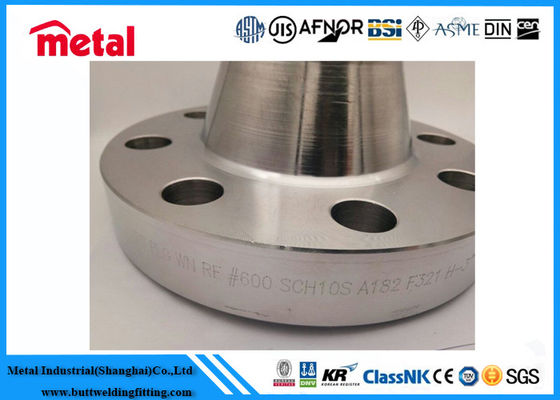

Stainless Steel RF Welding Neck Flange A182 321H For Connection

Specifications

1. Welding Neck Flange

2. sch5s-schxxs

3. ISO9001,ISO9000

4. Market:America,Africa,Middle East,Southeast of Asia

| Product Name |

Nickel Alloy Pipe Flange |

| Standard |

ASME/ANSI B16.5/16.36/16.47A/16.47B/B16.48, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Type |

Special Flange: According to the drawing Picture |

| Materials |

Copper Nickel Alloy: ASTM B466 UNS C70600, ASTM B466 UNS C71500, CUNI90/10, CUNI70/30

Nickel Alloy: ASTM/ASME S/B366 UNS N08020, N04400, N06600, N06625, N08800, N08810, N08825, N10276,N10665,N10675

Super Stainless Steel: ASTM/ASME S/A182 F44, F904L, F317L, UNS S32750, UNS S32760

Stainless steel: ASTM/ASME S/A182 F304, F304L, F304H, F316, F316L, F321, F321H, F347H

Duplex Steel: ASTM A182 F51, F53, F55, UNS S31803, UNS S31254

Alloy Steel: ASTM/ASME S/ A182 F11, F12, F22, F5, F9, F91

Carbon Steel: ASTM/ASME S/A105, ASTM/ASME S/A350 LF2, ASTM/ASME S/A694/A694M, F42, F52, F56, F60, F65, F70....

ASTM A516 GRADE 70

|

| Dimension |

(150#,300#,600#): DN15-DN1500

900# : DN15-DN1000

1500#: DN15-DN600

2500#:D N15-DN300 |

| Test |

Chemical Component Analysis, Mechanical Properties, Metallurgical Analysis, Impact Testing, Hardness testing , Ferrite Testing, Inter granular corrosion testing, X-ray Inspection (RT), PMI, PT, UT, HIC & SSC test, etc. or as your requirement |

| Certificates |

API, ISO, SGS, BV, CE, PED, KOC, CCRC, PDO, CH2M HILL and etc. |

| Advantages |

1. Abundant stock and prompt delivery

2. Reasonable for whole packages and processes.

3. 15 years' QC team service & sales management API& ASTM trained engineers.

4. More than 150 customers spread worldwide. (Petrofac, G.S Engineer, Fluor, Hyundai Heavy industry, Kuwait National Oil, Petrobras, PDVSA, Petrol Ecuador, SHELL, etc.)

|

Fatigue Resistance

The fatigue strength or endurance limit is the maximum stress below which a material is unlikely to fail in 10 million cycles in an air environment. For austenitic stainless steels as a group, the fatigue strength is typically about 35 percent of the tensile strength. However, substantial variability in service results is experienced since additional variables such as corrosive conditions, type of loading and mean stress, surface condition, and other factors affect fatigue properties. For this reason, no definitive endurance limit value can be given which is representative of all operating conditions.

OXIDATION RESISTANCE

316LN alloy exhibits excellent resistance to oxidation and a low rate of scaling in air atmospheres at temperatures up to 1600- 1650°F (870-900°C). The performance of ATI 316LN stainless is slightly inferior to that of ATI 304 stainless steel, which has slightly higher chromium content (18% vs. 16% for ATI 316LN stainless). The rate of oxidation is greatly influenced by the atmosphere en-countered in service and by operating conditions. For this reason, no data can be presented that is applicable to all service conditions.

Like other molybdenum bearing alloys, ATI 316LN stainless is subject to catastrophic oxidation at high temperatures in stagnant air atmospheres, such as in the heat treatment of closely packed items. This occurs due to the formation of low melting molybdenum trioxide (MoO3), which reacts with the alloy causing deep pitting and metal loss. When air is allowed to circulate, the MoO3 will evaporate from the metal surface and excessive oxidation is avoided.

CORROSION PROPERTIES

General Corrosion Resistance

The molybdenum bearing grades such as ATI 316 and ATI 316LN stainless steels are more resistant to atmospheric and other mild types of corrosion than the 18Cr-8Ni stainless steels. In general, media that do not corrode 18-8 stainless steels will not attack the molybdenum-containing grades. One known exception is highly oxidizing acids such as nitric acid to which the molybdenum bearing stainless steels are less resistant. ATI 316 and ATI 316LN stainless are considerably more resistant than any of the other chromium-nickel types to solutions of sulfuric acid. Where condensation of sulfur-bearing gases occurs, these alloys are much more resistant than other types of stainless steels. In sulfuric acid solutions, the acid concentration has a strong influence on the rate of attack.

Pitting Corrosion

Resistance of austenitic stainless steels to pitting and/ or crevice corrosion in the presence of chloride or other halide ions is enhanced by higher chromium (Cr) and molybdenum (Mo) content. A relative measure of pitting resistance is given by the PREN (Pitting Resistance Equivalent with nitrogen) calculation, where:

PREN = Cr + 3.3Mo +16N

The PREN of ATI 316LN alloy (25.0) is higher than that of ATI 304 (PREN =20.0), reflecting the better pitting resistance which ATI 316LN alloy offers due to its Mo and N content. ATI 304 stainless steel is considered to resist pitting and crevice corrosion in waters containing up to about 100 ppm chloride. ATI 316LN alloy on the other hand, due to its Mo-content, will handle waters with up to about 2000 ppm chloride. This alloy is not recommended for use in seawater (~19,000 ppm chloride). ATI 316LN alloy is considered adequate for some applications that are exposed to salt spray. ATI 316LN stainless steel exhibits no evidence of corrosion in the 100-hour, 5% salt spray (ASTM B117) test.

Packaging & Shipping

| Packaging: |

In wooded cases , pallets or according to clients' requirements |

| Shipping: |

Tianjin port, Shanghai port and the other main ports in China |

Our main products as follows:

- Stainless steel pipe & tube

(seamless pipe / welded pipe / square pipe / rectangular tube,duplex stainless / inconel tube)

- Carbon / alloy steel pipe & tube

(seamless pipe / ERW / SSAW / LSAW / UOE / hollow section pipe / Galvanized Pipe)

(line pipe,water pipeline,gas pipeline,oil pipeline)

(copper tube/titanium tube/aluminium tube/nickel alloy )

(round bar/angle steel /flat steel/channel steel/steel wire)

(eblows, equal / reducing tees, concentric/eccentric reducers, caps, crosses, bends, dish end/end cup, stub ends, unions, couplings / hex couplings, swage nipples , nipples, hex. plug, sockolet, weldolet, thredolet, etc)

(DIN flange/ AISI flange/blind flange/welding flange/stainless flange/slip on flange)

(stainless steel/carbon steel/alloy steel/galvanized steel/aluminium )

(ball valve/gate valve/butterfly valve/globe valve/swing check valve/ check valve)

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!